Advanced Toolform Z Level | WorkNC 2019 R1

WorkNC 2019 R1 brings the Z-Level Pattern to the Advanced Toolform technology, allowing the customer to use any tool shape to calculate the toolpath, using the Planar Finishing pattern on shallow areas, and the Z-Level pattern on steep zones of the part.

WorkPLAN Interface | WorkNC 2019 R1

The Interface with WorkPLAN reinforces Vero Software's commitment to improving the entire workflow of our customers, simplifying administration and ensuring consistency from quoting to delivery.

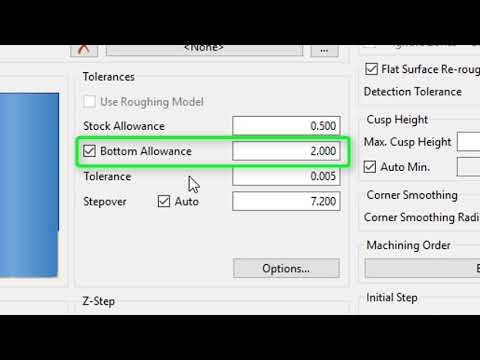

Bottom Allowance | WorkNC 2019 R1

Especially required by Electrode machinists, the separate allowance for the Z axis is a welcome improvement to WorkNC's renowned Roughing Toolpath.

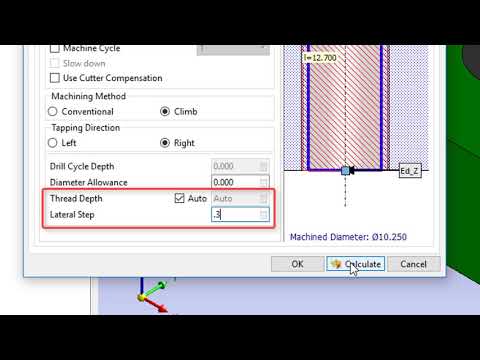

Lateral Passes Thread Mill | WorkNC 2019 R1

Another improvement that our existing customers will welcome, is the ability to set a lateral step to the Thread Milling, Contouring, and Chamfering toolpaths. Prior to this improvement, it was necessary to apply multiple toolpaths to achieve the same result.

Contour Remachining | WorkNC 2019 R1

Contour Remachining toolpath now allows you to define the toolpath you want to preserve, giving it Z ranges. This enables the user to specify different tool assemblies based on reach.